Sennheiser invests in sensiBel

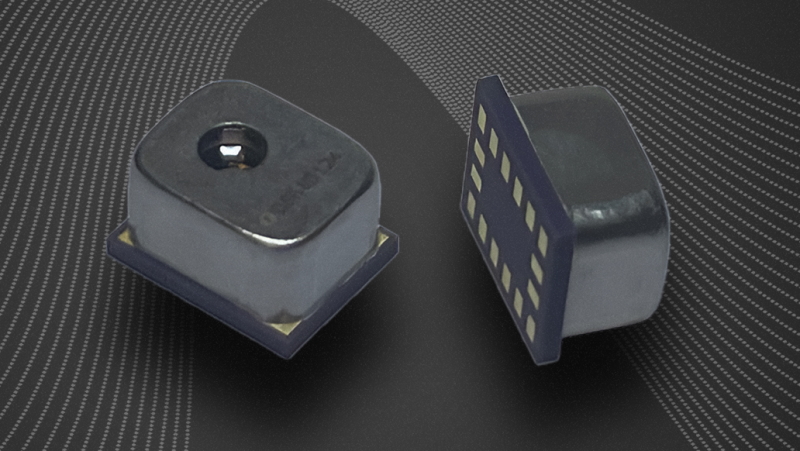

sensiBel MEMS

Sennheiser, together with existing investors, is investing 7 million euros in the Norwegian scale-up business sensiBel. The company has developed optical MEMS microphones which demonstrate first-class sound quality despite their miniature size. The miniature microphones enable a completely new and improved experience in application areas such as consumer electronics, automotive, conferencing solutions, and medical devices.

Constantly building the future of the audio world and creating exceptional sound experiences – that is the aspiration that drives the Sennheiser Group. Driven by this aim, the family-owned company is further expanding its strong position as a provider of professional audio solutions. "We want to grow sustainably as a company. In addition to investments in our existing business, this also includes investments in promising future fields outside of our company, providing these align well to our company and our vision," explains Co-CEO Daniel Sennheiser. Andreas Sennheiser adds: "sensiBel's innovative optical MEMS technology is clearly this type of promising emerging field. As investors, we look forward to actively driving forward this groundbreaking development."

sensiBel has developed a miniature microphone using optical technology that enables a generational shift in MEMS microphone performance, which is now sampling with lead customers. “sensiBel shares the same vision as Sennheiser and we are proud to welcome Sennheiser as investor,” says sensiBel CEO Sverre Dale Moen. He continues: “We believe an investment from such a highly recognized audio company speaks of the merits of the technology and the potential for optical MEMS technology to shape the future of miniature microphones.”

The distinctive feature of sensiBel’s unique technology is the use of light waves to measure the movement of the diaphragm. By contrast, conventional MEMS microphones measure an electric field between the moving diaphragm and a backplate. In sensiBel's optical system however, a laser generates light beams that are projected onto the microphone membrane and reflected on a photo detector. The reflected beams are captured and processed in an Application Specific Integrated Circuit (ASIC) with a digital output data interface. In contrast to the conventional method, this new technology makes it possible to measure very small movements and therefore capture very low noise levels – even when there is a high level of loud background noise. Additionally, the optical MEMS microphone can withstand high sound pressure levels providing a large dynamic range to the users. As a result, the microphones generate significantly better sound quality than previous MEMS solutions on the market – with a specification of 80 dBA SNR (14 dBA noise floor), 132 dB dynamic range, 24-bit digital output, and with low power consumption, while being just as compact.

How to resolve AdBlock issue?

How to resolve AdBlock issue?